THE HARDFACING OF MOULD & PUNCHES FOR CERAMIC TILES

THE HARDFACING OF MOULD & PUNCHES FOR CERAMIC TILES

Molds & Punches for ceramic tiles forming wear out quickly due to the strong abrasive-erosive action caused by the fine ceramic particles (powder) at each pressing cycle. In particular they wear out on the edges both of the mold and the punches. For this reason it is necessary to prolong their operating life through a wear-resistant hard coating made by welding.

This hard coating, once applied on the edges of the punches by robotized welding, must be further processed by milling and grinding to obtain the precise shape and size desired.

The characteristics of these welded hard coatings must be:

- High resistance to abrasion and erosion.

- Good machinability.

- Good weldability.

- Low heat input to reduce dilution and to prevent distortion of thin punches.

- Uniform, round, porosities and cracks free deposits.

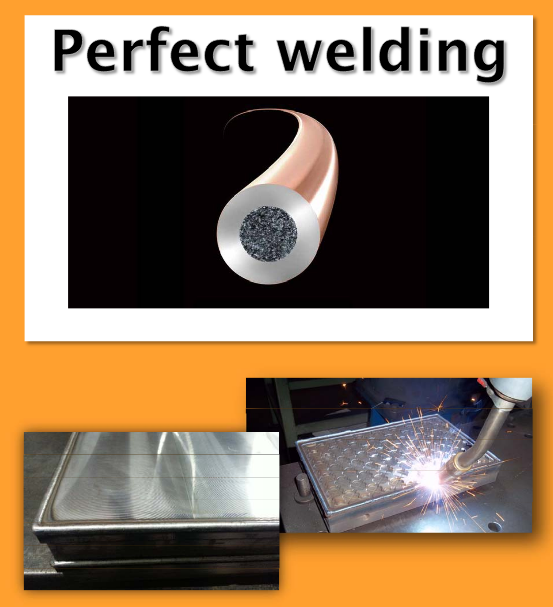

Considering all these features, MALLOY has developed a series of special SEAMLESS Flux-Cored hardfacing Wires for robotized welding of punches for ceramic tiles, to meet all technical-commercial needs:

|

MALLOY 444W, MALLOY 445W and MALLOY 446W All three welding wires offer good-excellent weldability, good looking and porosities/cracks free deposits. The difference between them lies in durability and machinability.

|

|||||||||||||

Special flux-cored hardfacing wire for punches edges for ceramic tiles, either new or worn

For information and prices, complete and submit the form below.